CATEGORIES

Latest news

Contact us

> Industry news

FDB bearing technology analysis: oil seal is not durable double roll too noisy

2017-05-15

For

the pursuit of the ultimate silent users, the double ball fan because

of its unique bearing sound difficult to use for a long time was

abandoned, and oil seal bearing fan because of shorter service life and

criticism, in this environment FDB (dynamic Hydraulic

bearings) bearing appears, in fact, this is a kind of oil lubricated

bearings, the use of oil film in exchange for better noise performance

and seismic performance. The author got ChipHell senior players monster wrote an article on the

FDB bearing the essay, hoping to help everyone understand the FDB

bearings.

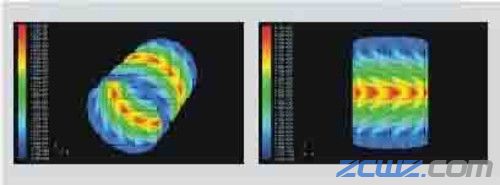

Dynamic

liquid bearings are usually used in the precision machinery industry,

it uses a mucosal oil bearing, oil film instead of ball. This can avoid the direct friction of the metal surface, the noise and

temperature is reduced to the lowest; while the oil film can

effectively absorb the vibration, so that the seismic capacity is

improved; more to reduce wear and improve life.

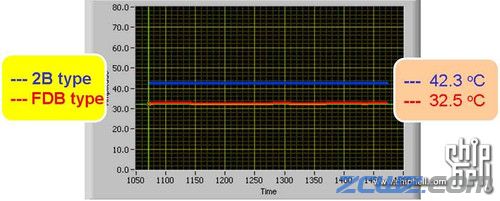

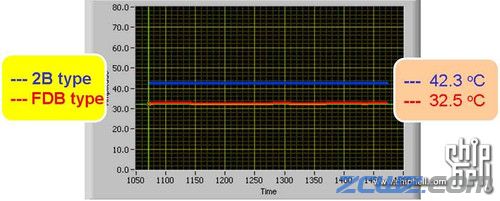

Test data 1: 8025 fan under the same conditions to run the corresponding time the temperature performance.

Test data two: 6.7MB in the background noise background, the fan

placed 1.0 meters away from the microphone, several fans of the noise of

three kinds of bearings contrast.

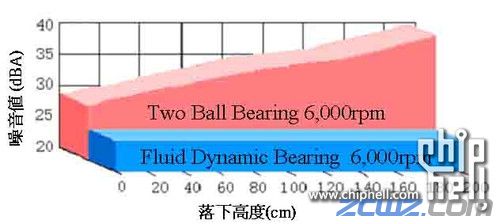

Test data three: with the specifications of double ball bearings and

FDB bearing fan at different heights after the noise performance

comparison.

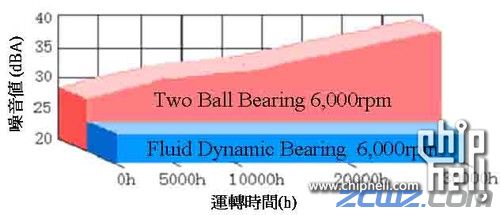

Test data three: with the specifications of double ball bearings and

FDB bearing fan in the long-term operation after the noise performance

comparison.

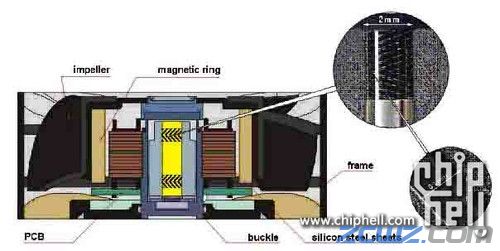

FDB bearing fan structure

FDB bearing DC fan works

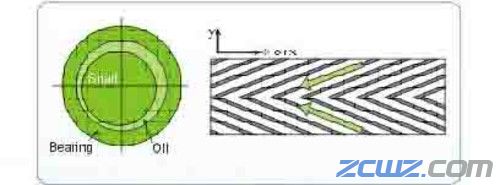

Because

the shaft shaft sleeve is filled with the right amount of liquid oil,

and the core processing time has a fine slot, the rotation starts, the

pressure of the oil to push the tip of the intersection (see below),

resulting in greater pressure so that the axis In the rotation is always separated from the sleeve, the friction reduced after the bearing life increased.