CATEGORIES

- DU - PTFE Coated Bushings

- DX - POM Coated Bushings

- FB090 - Bronze Bushings

- FB092 - Bronze Bushings

- JF - Bimetal Bearings

- GSB - Guide Slide Bushings

- JDB - Cast Bronze Bushings

- Ball Cage Retainer

- FU - Oil Sintered Bushings

- BTU - Ball Transfer Units

- SPB - Spherical Plain Bearings

Latest news

- Ferrofluid Vacuum Feedthrough Seals us

- Dry Bearing Bush

- Ball transfer unit

- Motorcycle suspension bushing

- Bimetal Flange Bush Bearing

- Selection standard for dimension refer

Contact us

- ADD: No.503,Hunan International Commerce Center, Jintai Square,Changsha 410001,Hunan.

- TEL: +86 731 84770165

- FAX: +86 731 84770163

- E-mail: sales3@slide-bearing.com

Powder Sintered Parts-PM Wrench

- Product description: Powder Sintered Parts-PM Wrench

PRODUCT INTRODUCTION

Powder sintered parts

1. Introduction of oil sintered bearing

1.1 Sintered Bronze bearings are all self-lubricating and maintenance free. The sintered bronze bushings consist of a porous bronze matrix impregnated with lubricant. The permissible sliding velocity for sintered bronze bushings is very high, which makes the bushings suitable for rotating applications.

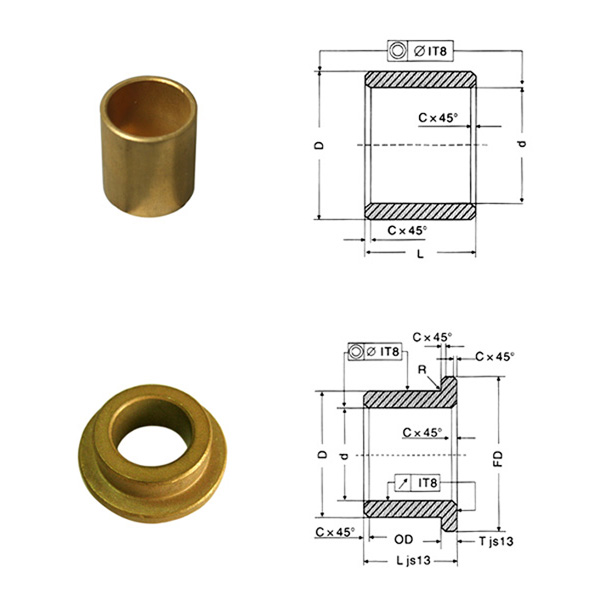

1.2 We offers a full range of both plain and flanged cylindrical bushings in accordance with ISO 2795.

2. Features and advantages

2.1 Very high sliding velocity

2.2 No external lubrication required

2.3 Maintenance-free operation

2.4 Good frictional properties

3. Material

3.1 Sintered Bronze/iron consists of a sintered metallic bronze or iron powder with fully impregnated porosity.

3.2 The material compositions are in bronze or iron or bronze-iron with a porosity volume of 12%-18 % impregnated with mineral oil.

3.3 Machining or grinding of the bearing surface of a porous sintered bushing is not recommended due to the risk of closing the bearing pores.

4. Applications

4.1Sintered Bronze bushings are most suitable for applications with rotating movements and where the self-lubricating performance requirements are high.

4.2 Examples of applications are:

4.2.1 Electrical equipment, like toys

4.2.2 Household equipment,like fans

4.2.3 Printing machinery

4.2.4 Machine tools,power tools

5. Lubrication

5.1 While storing and mounting make sure that the bushing never comes into contact with any absorbent material, as this may drain the oil very quickly.

5.2 It is therefore recommended to keep the bushing in the original packaging for as long as possible.

5.3 Additional lubrication is usually not necessary.

6. Specifications

|

Material |

Bronze |

Bronze(CuSn6Zn6Pb3/CuSn10) + 12~18%Oil |

|

Iron |

Fe + 12~18%Oil |

|

|

Cu-Fe |

Cu20Fe80 + 12~18%Oil |

|

|

|

Customized is available |

|

|

Load capacity |

|

35~45N/mm2 |

|

Speed limit |

|

2.5m/s |

|

PV value limit |

|

2.45N/mm2.m/s |

|

Yeild Strength |

|

147~294N/mm2 |

|

Hardness |

|

20~60HB |

|

Friction coef |

|

0.12~0.2 |

|

Working temperature max. |

|

-80~160°C |

7. Standard Types

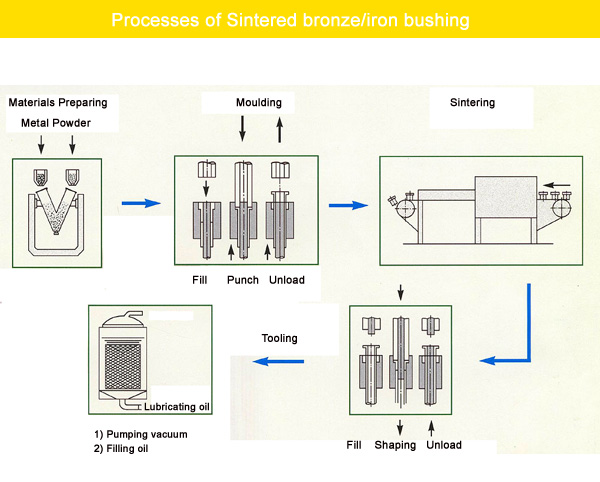

8. Production flow

General introduction of us

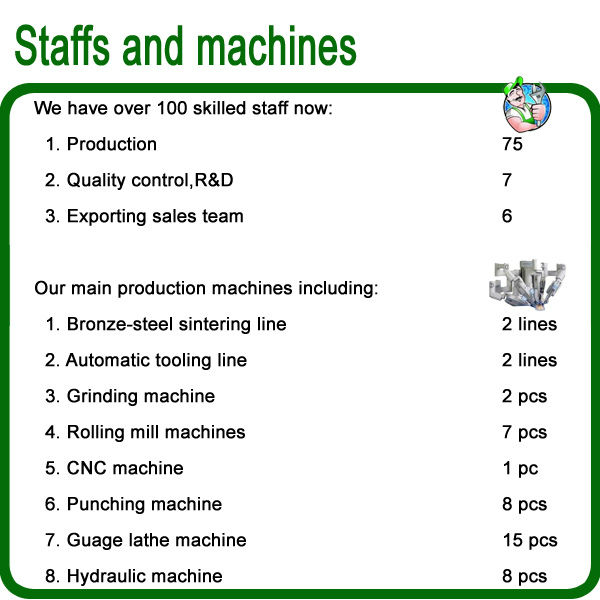

We are a professional manufactuer on various kind of bearings in China for over 14 years already.

With updated machinery and skilled staffs we have supplied stable high quality products to customers all over the world.

Our experianced engineers and exporting team can answer your inquiry or comment at the first time,and providing professional service from factory visiting, making orders to deliver goods.

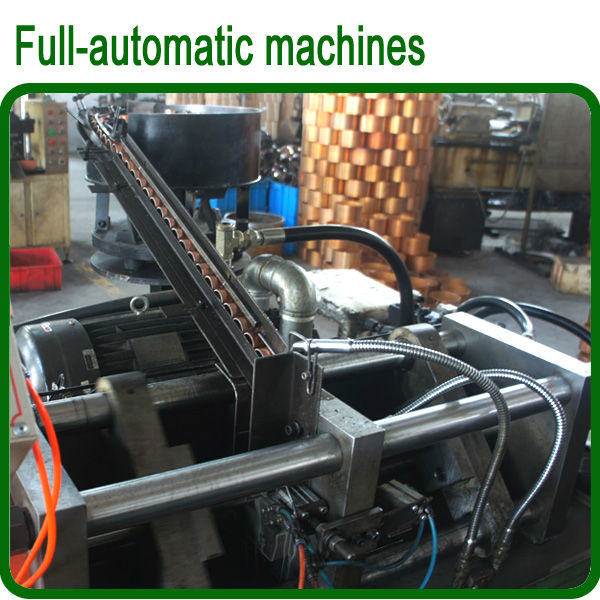

RIght now, we have over 100 skilled staff and different kinds of machines including automatic production lines,later machine,milling machine,CNC machine etc.

This picture showing our staff structure and basic machines list

This picture showing updated sintering machine and skilled workers in production

Our workshops are welcome you visiting:

This is our workshops buliding

We are using full new high quality raw materials only.

This is the bronze powder-steel backing sintereing line

This is a full automatic chamfering machine

Detail packing steps:

1.Clean bearings in anti-rust oil

2.Plastic films packing bearings to rollers

3.Bearings rollers put into plastic bag

4.Cartons with goods information label

5.Pallet for every 12ctns/24ctns/36ctns

Our packings are suitable for FCL or LCL sea shipping.

MOQ:1pc or 100pcs or 1000pcs(Different model and size have different requirement)

Delivery: you can choose different delivery ways for different qty orders.

Our quality management:

We will make inter inspection on every step of production.

Also you can order inspection company monitoring our production in our workshops.

1.ISO/TS 16949 Production Quality Management Certification

2.We will make measure guages calibration every 6 months

3.Record of calibration in certified lab

4.Certificate of lab